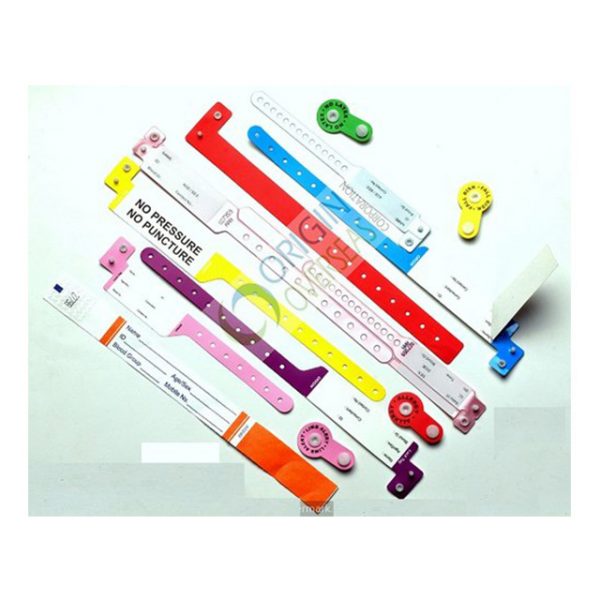

patient identification wrist bands

- Caremarque provides the highest quality and most comprehensive selection of Patient wrist bands and Alert tags.

- Accurate, Reliable, and easy to use while empowering the flawless delivery of care throughout the hospital – from admission to discharge.

- Our products are an integral part of the most successful patient safety initiatives at today’s top hospitals, enhancing clinical outcomes and operative efficiencies at critical points in the delivery of care.

Features

- As per International quality & standards

- Tear resistant

- Water resistant

- One time Locking

- Made in INDIA

- Customized Printing with Hospital Name & Logo